World-Class Manufacturing Facilities

Larsan Tin Printers operates with a strong infrastructure backbone to deliver high-quality metal packaging solutions. Our facilities are designed to meet global standards, ensuring efficiency, consistency, and precision in every stage of production.

Factory Units

Unit 1 to 3: Spread across 30,000 sq. ft., equipped with advanced machinery and streamlined processes for seamless tin manufacturing.

Unit 4: A state-of-the-art 50,000 sq. ft. facility, dedicated to high-volume production and specialized projects.

Advanced Printing & Coating

Imported Two Printing Lines for superior color accuracy, finish, and durability.

Imported Coating Line that enhances product protection and extends shelf life.

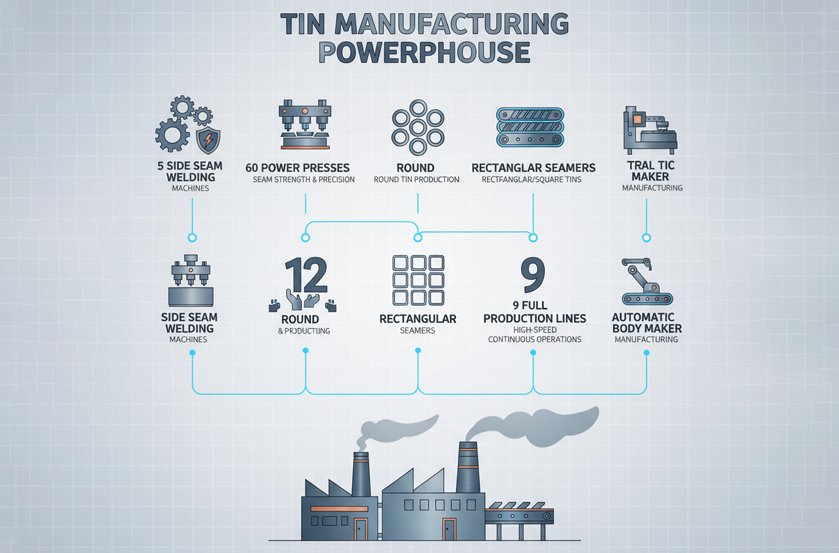

Production Capabilities

5 Side Seam Welding Machines – ensuring strength and precision in container seams.

60 Power Presses – for shaping and forming components with accuracy.

12 Round Seamers – ideal for round tin production.

8 Rectangular Seamers – catering to rectangular and square tin formats.

9 Full Production Lines – enabling high-speed, continuous operations.

Automatic Body Maker – for seamless side seam container manufacturing.

Warehouse & Storage

30,000 sq. ft. Warehouse Area – enabling safe, organized, and efficient storage of raw materials and finished goods.

Larsan Tins

Our Strength

With cutting-edge machinery, robust infrastructure, and skilled manpower, Larsan Tin Printers is positioned as a leader in tin manufacturing and decoration. Our facilities empower us to handle high-volume orders while maintaining unmatched quality standards.